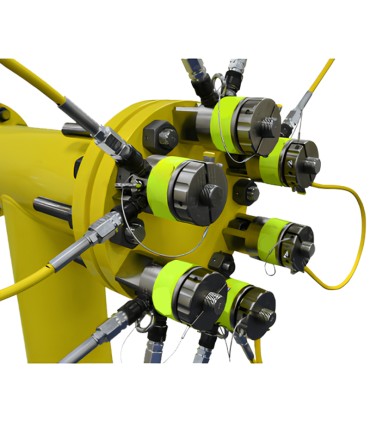

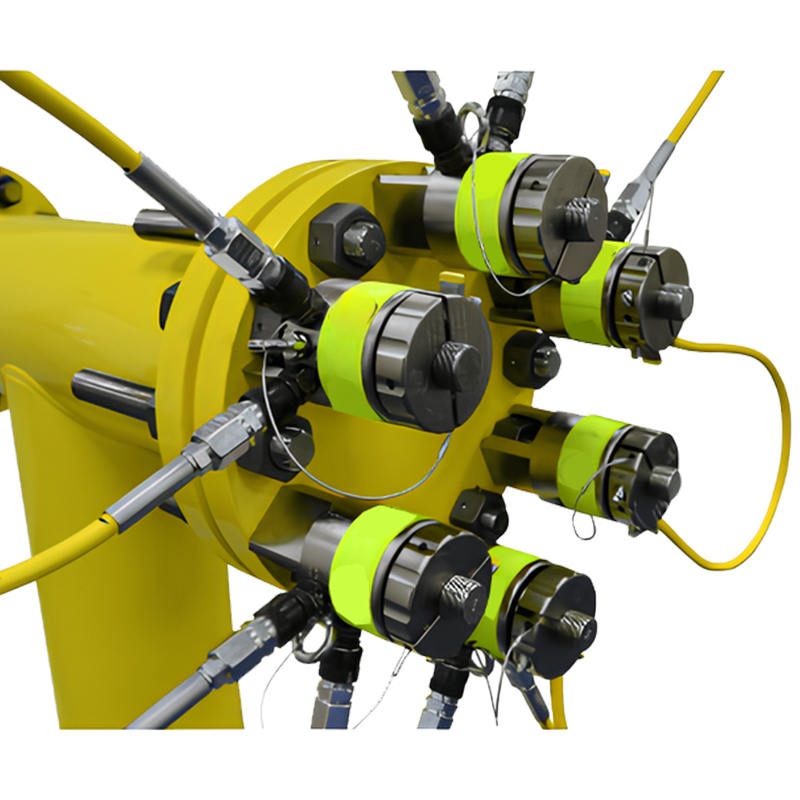

240 kN Subsea Bolt Tensioner

- Model code WST2

- Capacity range 237 kN

- Sizes M24 to M30 and 1” , 1-1/8”

- Piston stroke up to 30 mm except WST1

- 7 different load cells cover all ranges

- Working pressure 1500 bar maximum

- Twin in-output ports in each load cell

- Special protection against corrosion

- Anti-slip surface for more secure handling

- Auto compensation for misalignments

- Overstroke prevention without leakage

- Rapid securing or reliable reaction nut

- Load cell accompanied by a tommy bar

Subsea Tensioners - Load Cells – High-Performance Solutions

Aquajack subsea hydraulic tensioners provide a highly economical method for tightening bolts or studs underwater. They can be quickly and accurately positioned even in low visibility environments, thanks to their compact design and extended piston stroke. The innovative Split Nut feature of these tools enables swift application to extended bolts and those with damaged threads, as well as quick removal of the tool.

Datasheet Datasheet |

WST Subsea Bolt Tensioner Datasheet |

|

|

|

|

|

Bolt Tensioners Technichal Table

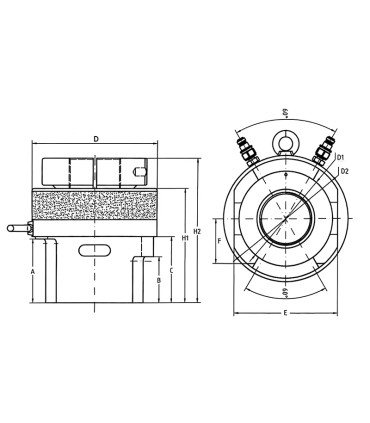

| Model | Size | Force | Stroke | Hydraulic Effective Area | H1 | H2 | B | D1 | D2 | D | Min. Bolt Length | ||

| Metric | Imp | kN | mm | in² | mm² | mm | mm | mm | mm | mm | mm | mm | |

| WST1 | M20 | 3/4” 7/8” |

141 | 20 | 1.96 | 943 | 96 | 117 | 38 | 45 | 60 | 66 | 107 |

| M22 | 105 | ||||||||||||

| WST2 | M24 | 1” 1-1/8” |

237 | 30 | 2.45 | 1585 | 127 | 147 | 51 | 56 | 75 | 82 | 139 |

| M27 | 136 | ||||||||||||

| M30 | 134 | ||||||||||||

| WST3 | M33 | 1-1/4” 1-3/8” |

379 | 30 | 3.92 | 2532 | 137 | 162 | 58 | 67.5 | 92 | 97 | 142 |

| M36 | 139 | ||||||||||||

| WST4 | M39 | 1-1/2” 1-5/8” |

551 | 30 | 5.69 | 3676 | 145 | 169 | 63 | 80 | 106 | 111 | 147 |

| M42 | 144 | ||||||||||||

| WST5 | M45 | 1-3/4” 1-7/8” 2” |

880 | 30 | 9.10 | 5868 | 158 | 189 | 73 | 96 | 124 | 136 | 160 |

| M48 | 158 | ||||||||||||

| M52 | 154 | ||||||||||||

| WST6 | M56 | 2-1/4” 2-1/2” 2-3/4” |

1564 | 30 | 16.17 | 10433 | 180.5 | 223 | 92.5 | 129 | 166 | 177 | 178 |

| M60 | 175 | ||||||||||||

| M64 | 172 | ||||||||||||

| M68 | 169 | ||||||||||||

| M70 | 165 | ||||||||||||

| WST7 | M76 | 3” 3-1/4” 3-1/2” |

2419 | 30 | 26.63 | 16128 | 202 | 255 | 82 | 163 | 205 | 217 | 195 |

| M80 | 192 | ||||||||||||

| M85 | 188 | ||||||||||||

| M90 | 184 | ||||||||||||

Bolt Tensioner Size Table (mm)

| Model | A | B | C | D1 | D2 | E | F | G | H1 | H2 | Weight |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | kg | |

| WST1 | 33 | 38 | 40 | 45 | 60 | 48 | 19 | 66 | 96 | 117 | 1.7 |

| WST2 | 45 | 51 | 56 | 56 | 75 | 60 | 24.5 | 82 | 127 | 147 | 3 |

| WST3 | 50 | 58 | 63 | 67.5 | 92 | 77 | 28 | 97 | 137 | 162 | 6 |

| WST4 | 53 | 63 | 68 | 80 | 106 | 90 | 28 | 111 | 145 | 169 | 7 |

| WST5 | 58 | 73 | 77.5 | 96 | 124 | 114 | 40 | 136 | 158 | 189 | 11.2 |

| WST6 | 78 | 92.5 | 97 | 129 | 166 | 140 | 50.5 | 177 | 180.5 | 223 | 213 |

| WST7 | 113 | 82 | 117.5 | 163 | 205 | 180 | / | 217 | 202 | 255 | 33.6 |

Key Features:

Capacity Range: Available in metric sizes from M20 to M90, and imperial sizes from 3/4” to 3-1/2”, catering to a wide variety of applications.

Working Pressure: Built to withstand working pressures of up to 1500 bar, ensuring high performance in even the most demanding environments.

Extended Piston Movement: Designed for extended piston travel, allowing for more flexibility and capability in your operations. Piston stroke up to 30mm.

Streamlined and Compact Structure: The compact, streamlined design ensures minimal space requirements while maintaining optimal functionality.

Misalignment Compensation: Our products are engineered to compensate for misalignments, enhancing reliability and reducing the risk of damage during operation.

Effortless Hose Attachment: Designed for fast and easy hose connections, ensuring quick setup and operational efficiency.

Clear Indication of Piston Movement: Equipped with easy-to-read indicators to clearly display piston movement, making monitoring and control more efficient.

Overstroke Prevention with No Leakage: Built-in overstroke prevention ensures there’s no leakage, providing safe and efficient operation.

Rapid Securing or Reliable Reaction Nut: Our products include features that allow for fast securing and a reliable reaction nut for greater stability and precision.

Load Cell with Tommy Bar: Each load cell comes with a Tommy Bar for easy installation and operation, providing added convenience.

Whether you need precision load measurement, powerful hydraulic force, or a combination of both, our products deliver performance you can count on. Explore our range today to find the perfect solution for your industrial needs.